Someone once said that if the competition is talking about you, it means that you are doing something right. During recent months we have seen an increasing number of campaigns aggressively comparing eco-solvent with HP Latex technology.

It turns out this is not by chance – since the launch of the HP Latex 300 series, HP has risen to the number one market share position worldwide in the Low Volume Sign Market category, according to IDC.

Our customers are the ones who have made HP Latex so successful. Their feedback has driven the improvement of this technology with each new generation. With their experiences in mind, I would like to give you my perspective on why HP Latex has proven so popular, and clarify some false statements that our competitors are making.

So, when you’re comparing HP Latex to eco-solvent printers, consider these 5 critical areas before you buy.

1- Value for Money

The price of the equipment is usually the first thing being compared, but many comparisons are really ‘apples to oranges’. Printer price usually correlates with printer speed, and most vendors publish what we call the ‘box spec’ or maximum speed, but this doesn’t tell the whole story.

Instead, look at the different print modes and speeds that give similar print quality. My suggestion is to compare speeds for similar indoor quality (short distance viewing) as well as speeds for similar outdoor quality (long distance viewing). This will help you to compare ‘apples to apples’ and evaluate prices for similar printer performance.

You should also consider what else is included in the box at the given price. Some models, including HP, include a ‘RIP in the box’ intended to make it easy for customers with low print volumes to get started. But as your print volume and demand complexity increase, you will need a more professional RIP, such as those offered by Onyx, Caldera and others. This is why HP only offers a RIP in the box with our HP Latex 310 and 330 Printers, but not with the higher performance HP Latex 360.

Finally, consider also warranties (and what they really cover, especially when related to print heads), supplies and other services included. For instance, the HP Latex 360 includes a spectrophotometer, and HP offers free services like the HP Latex Mobile application, and the HP Wallart solution – both across the latex portfolio.

Be sure you make a true value comparison when looking at printer prices.

2- Ink and other running costs

Let’s talk about the price of the inks. Or better, I should say, the total running costs. Ink price per liter is the simplest comparison. But, you should also consider ink efficiency, which is how much ink you need to print an image. There are industry standard tests we use that support our HP Latex claim of 17 cents per square foot with the 300 series – this is comparable to most eco-solvent printers using original inks.

However, this test does not include ink wasted in printhead cleaning and other maintenance routines. For HP Latex this ink waste is negligible, but for many eco-solvent printers, this waste can easily add 5-10% to your total ink usage, especially if your printer usage is low.

Printheads & cleaning consumables should also be included when calculating running costs. HP Latex uses thermal inkjet technology – these are user replaceable consumables, and on average add an extra 3 cents per square foot. The big advantage is that your image quality will be always to the level of a brand new printer.

Eco-solvent printers use piezo technology printheads. These do last much longer but are much more expensive; also, the print quality degrades over time – piezo heads use a mechanical pulse and wear out. And if you have a paper crash and damage several heads (usually the main reason for a printhead change), it could cost you thousands of dollars plus a service intervention that is not covered by the warranty. So, a fair cost comparison should take into account that you will need to change on average 1-2 print heads per year on an eco-solvent printer in order to keep the original print quality during its life.

Finally, cleaning consumables are different by technology, but in general, have a similar cost and add less than 1 cent per square foot.

In summary, HP Latex 300 printers will cost you on average around 21 cents per square foot to run all things included, very comparable to most eco-solvent printers using original inks. And we also have a bigger supply configuration for customers with high print volumes (the HP Latex 370).

3- Substrates and Applications

The next point you need to consider when comparing eco-solvent and HP Latex is the media breath and application coverage. This is one of the most important benefits of latex compared to solvent, due to the huge range of flexible materials, coated and uncoated, that you can print with HP Latex. It’s not only about doing vinyl and banners but expanding to films, papers, textiles, canvas, wallpaper, and many more. And now with the 300 series, we also support heat sensitive materials like most popular cheap banners and polypropylenes.

Contrary to what people think, solvent-based inks work well on non-porous substrates like banners and vinyl, but need special coating in porous materials like papers, textiles or canvas – otherwise, the pigments penetrate into the media and you get a dull image. A big benefit of HP Latex technology is that the pigments stay in the surface so you can print with high quality even on uncoated porous substrates, saving the cost of the coating. That’s the reason why many canvas producers are moving to HP Latex, for instance.

My recommendation, however, is that you should ask for samples and experience yourself – seeing is believing!

Order a sample book here:

4- Image Quality & Durability

Image quality is a broad term with plenty of technical considerations. Both eco-solvent and HP Latex give excellent image quality and color gamut, almost photo-realistic. The big advantage of HP Latex is how easy it is to get this quality and sustain it print after print across a wide range of applications.

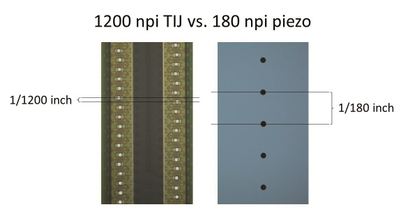

Some vendors base their image quality claims on the fact of having grey scale - a term used in piezo technology to say that you can fire different drop sizes. This concept is important for piezo technology, but not really relevant for comparing to Thermal Inkjet Technology (TIJ) used in HP Latex.

The HP TIJ printheads are high-resolution printheads with 1200 nozzles per inch, compared to the 180 nozzles per inch that current piezo printheads have.

This means that we can use as much or as little ink as the image requires without the need to manage complex variable dot sizes. Another advantage of so many nozzles is that we can automatically substitute any missing nozzle by other working nozzles. This is done in HP Latex with automatic compensation algorithms so the image quality is always at its best.

So the most important in the quality consideration is not this spec or that spec, as each technology has its own ones, but that you get the quality you expect, at the speed you expect, print after print.

After print quality, print durability is also a big one. Let’s consider two aspects of durability – light fade and scratch resistance.

Regarding light fade, both eco-solvent and HP Latex use pigmented inks, and as a result, give a similar light fade performance. As a general rule, you should expect up to 3 years un-laminated outdoor life and up to 5 years laminated, if you are using good quality branded substrates like 3M and others. Take into account that adverse display conditions (direct sun, high humidity) or not high-quality substrates will affect life considerably.

What is unique to the third generation of HP Latex Inks is their scratch resistance. Eco-solvent prints are easy to scratch – just try it with your fingernail – so most of the time you will need to laminate them. The third generation HP Latex Inks have an anti-scratch agent that protects the print – this is most noticeable on smooth surfaces such as vinyl or PVC banner. This considerably reduces the risk of accidental damage during finishing, installation, and display, to the extent that you may be able to avoid lamination for short term applications.

This scratch resistance is another feature customers love on the third generation of HP Latex Inks.

Scratch resistance test samples – competitor eco solvent on left and HP Latex on right.

5- Same day delivery

The last point to consider is, in fact, the most important: your ability to respond fast to your customers’ needs, even when they ask for same day delivery.

For sure print, speed is important, but not enough. Most of the applications produced with eco-solvent are laminated, and before applying the lamination, you must ‘degas’ the print by leaving 24-48 hours for the solvents in the print to evaporate; otherwise, you will get bubbles appearing under the lamination after a few days. So even if you have the fastest eco solvent printer, you will still need to wait 24-48 hours to finish and deliver it.

HP Latex inks do not have this problem – they are completely dried inside the printer, and prints are ready to finish and ship as soon as they come out of the printer as there are no solvents to evaporate.

This is a huge business advantage and surely the main reason why eco-solvent users are converting to HP Latex.

Don’t take our word for it – ask around, try it yourself

I would like to finish by recommending you that never rely only on what a manufacturer says, even if it’s HP!

You should talk to some current latex users you may know, or ask your dealer for reference customers, and take a look at what’s being said on the web, good and bad. But most importantly, make sure you try it yourself – ask for a demo, get some print samples, bring your own files and substrates and test it yourself.

This is an important investment you are making, and your business depends on it, so base your decision not only on which printer gives you the best value for money, but also which company are you partnering with for success.

More resources for making a smart comparison

Thank you for reading this far; I hope you found the post useful. I will comment about the environmental benefits of HP Latex in another post. And for any doubts, you may have – or if you want to learn more about HP Latex – I encourage you to register in the HP Latex Knowledge Center, so you can actively participate in our HP Latex forum and be unstoppable!