How to prepare the printer for an extended downtime

NOTE: All the actions described below can be performed by the customer, except the ink tubes flush. If this action is required, it should be done by your service representative.

The white ink, due to its composition, must be recirculated constantly through all the White IDS system to ensure the printing conditions. Not meeting this requirement might end up damaging the printheads and the rest of the IDS components, as well as clogging the white ink tubes.

IMPORTANT: If the procedure described below is not followed, the white printheads and white ink line will most probably get damaged.

Due to this requirement, the printer has been designed to preserve the white ink channel without the need of rearming the printer and to minimize the power consumption when the printer is not being used. To run in this low power mode the printer needs to be connected to the electrical supply.

1. Extract the white printheads from the carriage and store them in the maintenance wheel.

2. Insert the auxiliary printheads in the carriage to allow the white recirculation routines.

3. Remove the tank cap and empty the water tank using a manual siphon pump.

The siphon pump should be purchased locally if not available.

4. Run the 47009 Distilled water system check diagnostics about 5 times to remove the remaining water in the tubes.

5. Change the printer to Low power mode.

IMPORTANT: There should be at least 500 ml of ink remaining in the white supply. If the amount of ink remaining in the white supply is lower, replace the ink supply prior to change the printer to low power mode.

a. Tap the power icon, at the right top of the IPS screen and select Switch to low power mode.

b. The printer will boot up in low power mode. To confirm this status, the beacon will remain blinking on green and the top bar in the IPS screen will be shown in green as well.

NOTE: In the event of an electrical failure at the customer site, the printer will restart automatically in the Low power mode once the power supply has been restored.

6. The main printer, switch (2), can be lowered.

It is recommended to keep the IPS computer ON to check remotely any malfunction in the low power mode routines.

IMPORTANT: The E-box switch (3) should always be enabled. It is also recommended to enable the IPS switch (1).

7. Check that the orange printhead caps are available and the rubber is in good condition. If they are not available, or the sealing rubber is not in good condition (broken or deformed), keep the printheads in the carriage and make sure the carriage is left in the capping station when turned OFF.

8. If the orange caps are available, gently clean the black sealing rubber inside with a lint-free microfiber cloth and distilled water in order to remove any dried ink or fibers that could be present. Once clean, make sure to completely dry the black sealing rubber with a dry lint-free microfiber cloth before capping the printhead.

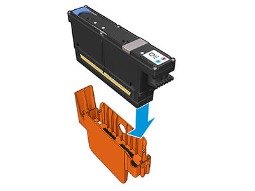

9. Remove the color, overcoat and optimizer printheads and store them in their orange protective caps. Also make sure to cover the printhead needles with the orange protector rubber as shown in the image below.

IMPORTANT: Ensure that each printhead uses its own orange sealing cap and not one from another color printhead. This is especially important with the optimizer printhead caps, as there’s a risk of nozzle damage if they are mixed with the color printheads.

IMPORTANT: If the orange caps (plastic and rubber protector) are not available, leave the printheads in the carriage. The carriage should be in capping position.

10. Store the color, overcoat and optimizer printheads vertically in upright positions as show below with the orange cap facing up.

IMPORTANT: Ensure that each printhead is stored with the orange caps facing upwards. Otherwise, the printheads will most probably get damaged.

11. Disconnect the color, overcoat and optimizer ink cartridges.

IMPORTANT: Make sure that:

- The power switch for the “E-box and ink white” remains on. Recommended as well the “IPS” one.

- The auxiliary printheads are inserted in the carriage.

- The white supply and white intermediate tank are properly installed and connected.

- There should be at least 500 ml of ink remaining in the white supply. If the amount of ink remaining in the white supply is lower, replace the ink supply prior to change the printer to low power mode.

Additional considerations regarding ink flushing and the color intermediate tanks

- If the temperature is below 5 °C/41 °F, the IDS (Color and White) should be flushed.

Call your service representative to empty the ink from the tubes.- Keep the removed materials (supplies, intermediate tanks, and printheads) above 5 °C/41 °F.

IMPORTANT: Ensure that the removed materials are stored in the above recommended environmental conditions. Otherwise, they may get damaged.

- If the temperature is above 5 °C/41 °F:

- Color IDS does not need to be flushed.

- White IDS should be flushed if the printer is completely turned off for more than 1 week (only if the low power mode is not enabled). Call your service representative to empty the ink from the tubes.

IMPORTANT: If the low power mode is not enabled and the printer is switched off, the white ink line needs to be flushed. This procedure should be done by a certified service engineer. Otherwise, the white ink line may get clogged and require a service intervention to recover the printer.

- Color, optimizer and overcoat intermediate tanks:

- If the printer is not flushed and the room temperature is not stable, it is better to keep the intermediate tanks installed to compensate volume changes due to temperature variations.

- In case of a stable temperature, the intermediate tanks should be disconnected.