How to prepare the printer for an extended downtime

Only carry out the following procedure if the expected downtime exceeds 2 weeks. If the expected downtime is less than 2 weeks, leave the printer (ON or OFF) with the printheads in the carriage and the carriage in the capping position.

NOTE: All of the following actions can be performed by the printer operator, except flushing the ink tubes. If this action is required, it should be done by a certified service engineer.

If you need to move your printer or store it for an extended period of time, prepare it correctly to avoid possible damage.

1. Do not remove the ink cartridges or maintenance cartridge.

2. If the orange (white or transparent for the optimizer printhead) caps that came with the printhead are available, gently clean the black sealing rubber inside with a lint-free microfiber cloth and distilled water, in order to remove any dried ink or fibers that could be present. Once clean, make sure to completely dry the black sealing rubber with a dry lint-free microfiber cloth before capping the printhead.

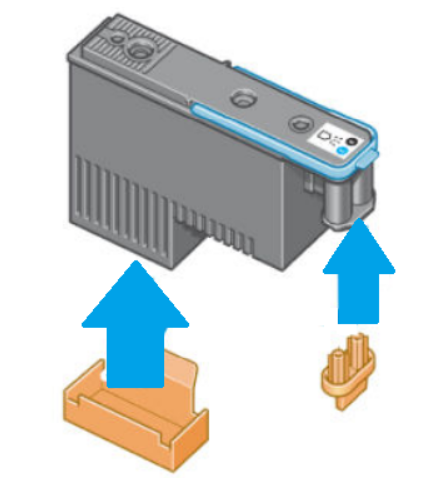

3. Remove the printheads and protect them with the orange (white or transparent for the optimizer printhead) caps. Make sure to cover the printhead needles with the orange protector. Once the printhead has been removed, store it in an upright position with the orange caps facing upwards. If the caps are not available, it is better to keep the printheads installed in the printer.

IMPORTANT: Make sure to remove the printheads only if the orange (white or transparent for the optimizer printhead) caps are available. Otherwise, the printheads will probably get damaged.

IMPORTANT: Ensure that each printhead uses its own sealing cap and not one from another color printhead. This is especially important with the optimizer printhead caps, as there is a risk of nozzle damage if they are used with the color printheads or vice versa.

IMPORTANT: Ensure that each printhead is stored with the orange cap facing upwards. Otherwise, the printheads will probably get damaged.

4. (Only for the Latex 500 Printer Series) Make sure you empty the condensation collector. Remember to connect the cap to the condensation collector after emptying it.

5. Make sure that no substrate is loaded.

6. Make sure that the printhead carriage is located in the service station (at the right end of the printer).

7. Make sure that the “Ready” message appears on the front panel.

8. Turn off the power by using the power button on the front panel.

9. Also, switch off the power switch at the rear of the printer.

10. Disconnect any cables that connect the printer to a network, a computer, or a scanner.

11. Close all doors and covers.

12. If you intend to turn the printer upside down, first remove the maintenance cartridge (see how to replace the maintenance cartridge in the printer User’s Guide) and also remove the printheads if these are still installed in the printer.

13. For correct environmental storage conditions, see Environmental specifications in the User’s Guide. Take into account that optimal condition for printer, ink cartridges, and printheads during shut down are 59°F to 86°F (15°C to 30°C) and 20% to 70% relative humidity.

a. If the printer is going to be exposed to temperatures below 41°F / 5°C, a certified service engineer is required to flush the ink lines from the printer.

IMPORTANT: Ensure that the printheads are stored in the above recommended environmental conditions. Otherwise, the printheads may get damaged.

NOTE: If the printer or ink cartridges are moved from a cold location to a warm and humid location, water from the atmosphere can condense on the printer parts and cartridges and can result in ink leaks and printer errors. In this case, HP recommends that you wait at least 3 hours before turning on the printer or installing the ink cartridges, to allow the condensation to evaporate.