How to improve Banner Production printing with HP Latex Printers

1. Overview

This document is intended for:

• Owners and operators of any HP Latex Printer, with special focus on HP Latex 300 series printers and HP Latex 500 series printers

• HP Latex Customer Support, marketing, and sales organizations

This document provides information about:

• Different classes of banner media

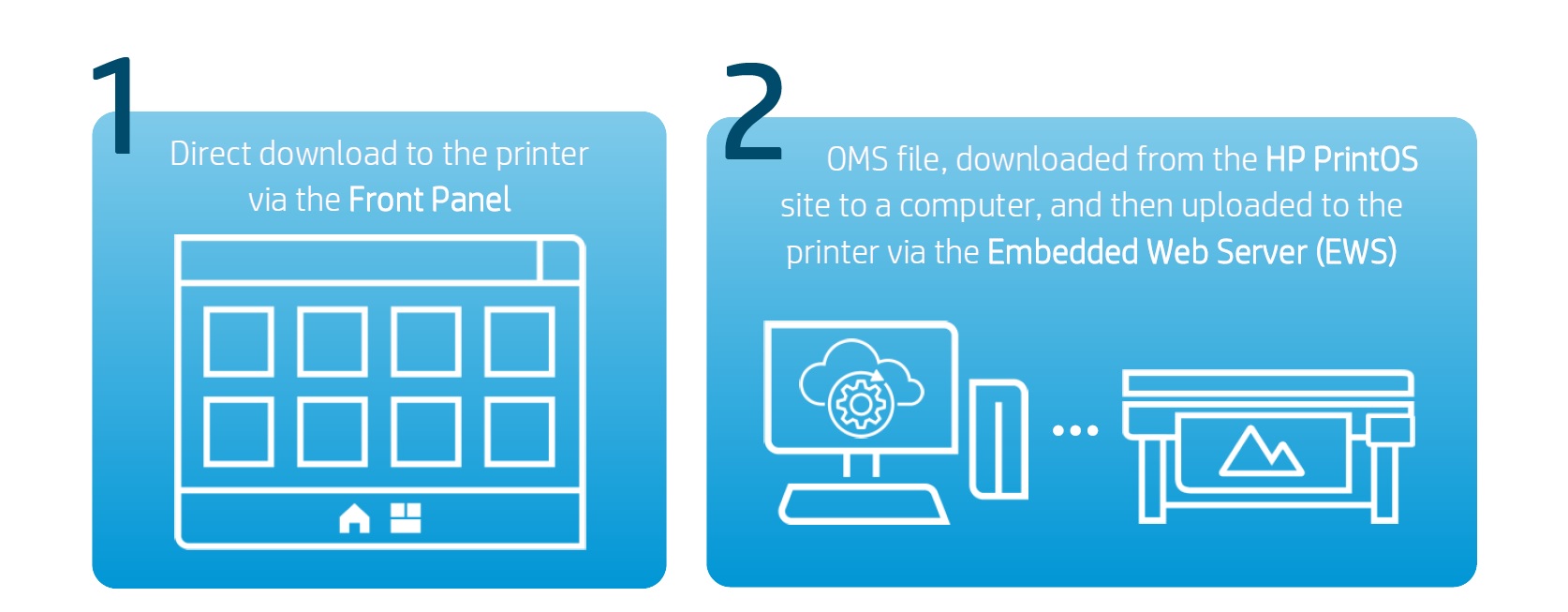

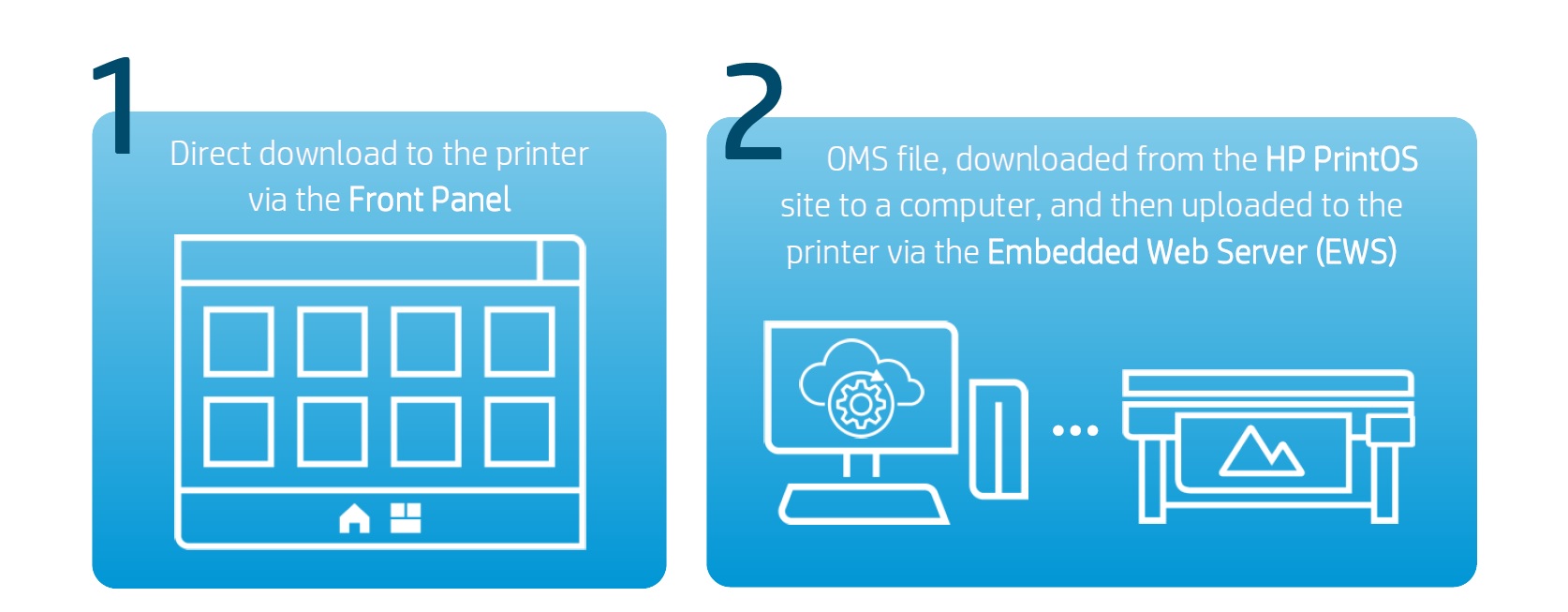

• Where and how to obtain Media Presets (aka profiles)

• RIP-based tools to automate banner production

2. Introduction to Banner Production

HP Latex Printers can print onto a very wide range of banner media, ranging from the most inexpensive bond papers and scrim banners, to smooth double-sided banners, to woven and sustainable banners for specialty applications.

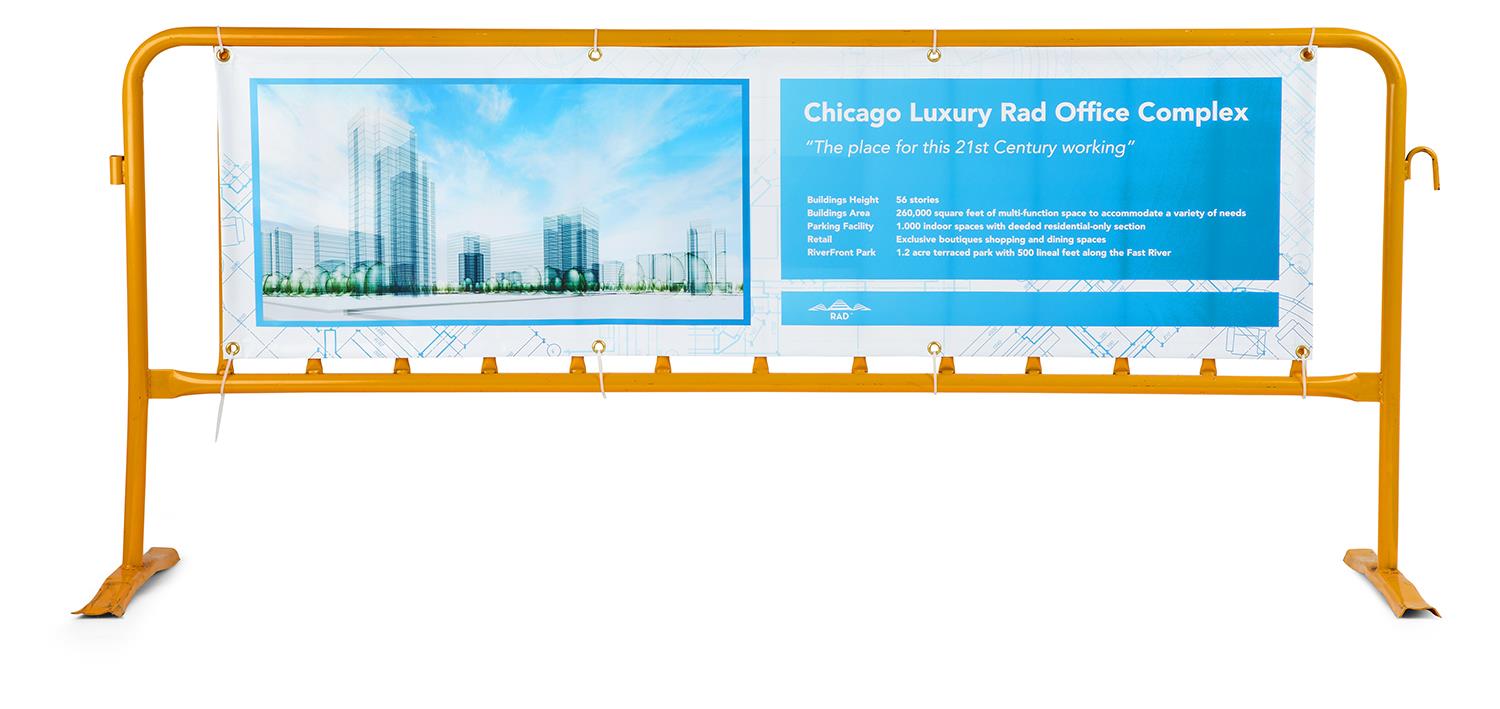

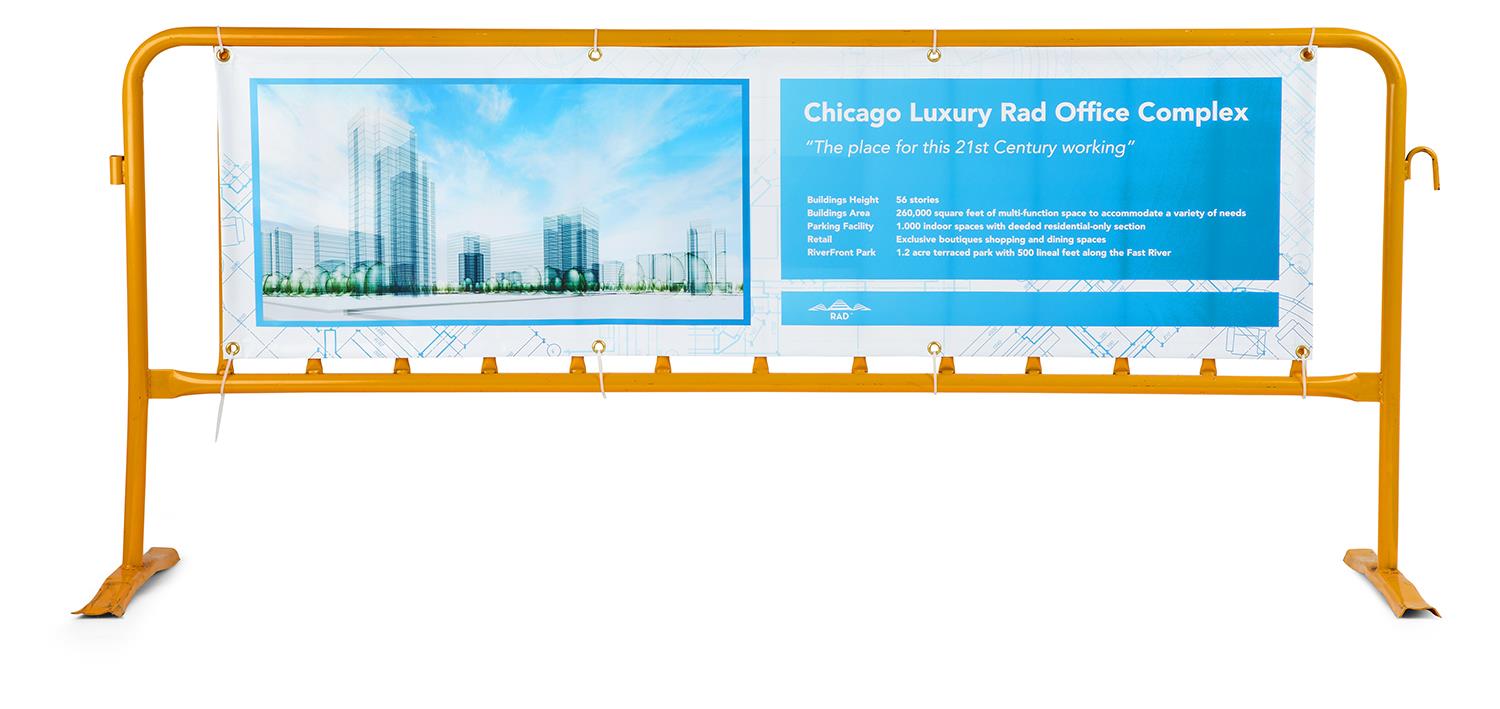

Banners are a sign industry staple product that are widely available. Banners are used in both interior and exterior locations, and while they should be considered short-term products, even in exterior applications, they can last several years or more when properly mounted and secured.

Banner media can be made from PVC, Tyvek, HDPE, Polypropylene, polyester film and fabrics, and other substrates.

Banners are typically printed, trimmed, and finished, before being installed and mounted. Banners are almost never laminated using film laminates.

With current HP Latex printers, inks are highly durable and scratch-resistant. While exterior banners are not considered long-term products, their longevity is largely dependent on where and how they are mounted.

Many banners are printed on one side only and are referred to as single-sided banners. Double-sided banners are widely used in some applications, including pole banners. Double-sided banners should be produced using block out banner media.

The HP Latex 365 and 500 Series printers include the ability to auto-register the two sides, making double-sided banner production fast and easy.

3. Banner materials

HP has certified several brands of heat transfer materials and profiles that are available at HP’s Media Locator (www.printos.com/ml/#/medialocator) or are directly downloadable from the HP Latex printer’s front panel:

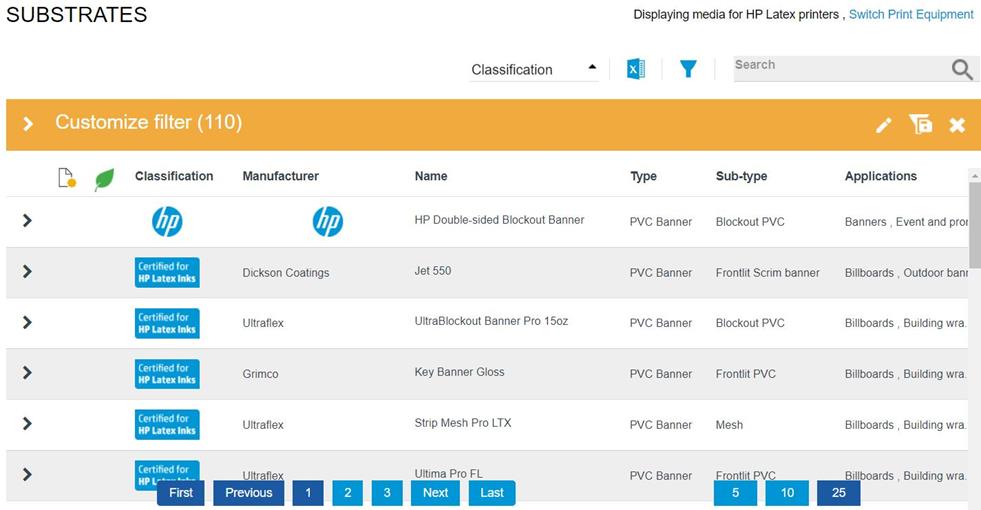

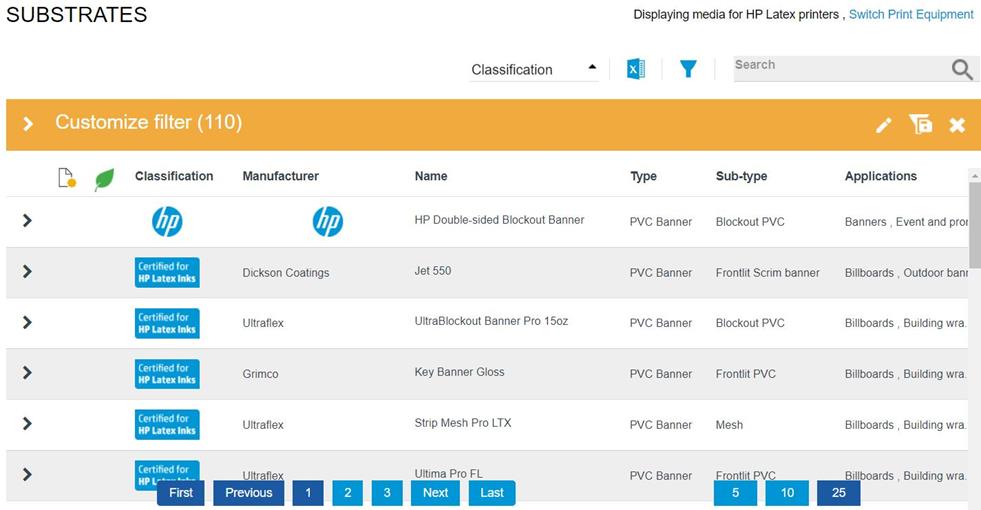

There is a wide range of HP, Certified, and Profiled media products listed on the HP Media Locator site, with over 100 different PVC-based banner products listed for the Latex 300 Series printers.

Certified media has passed a rigorous and comprehensive battery of tests, ranging from ink adhesion and runability through trimming and finishing. Profiled media has passed benchmark tests for ink adhesion and runability in the printer.

Many scrim PVC banner media are manufactured in Asia and are being imported to the North American market under OEM arrangements by sign supply resellers. Most of these products are compatible with HP Latex printers.

Other media are brought to market under manufacturer branding. Some of the manufacturers in this market space include HP, Starflex, Cooley, and Bantex. All HP Latex printer models can accommodate substrate wound in either direction – print side in or print side out.

Below is a screen shot of the HP Media Locator, where a filtered list of 110 banner media are referenced. Each of these Media Presets are available for download directly to the printer.

The Media Preset controls all of the mechanical parameters required for successful print production on the referenced media. These mechanical parameters include one or more pass counts (print modes), temperature settings that have been tuned to the media, and a host of additional settings. Media Presets always include color data, such as reference Color Calibration and ICC profile data.

4. RIP-based Tools for Banners

RIP software from SAI ships with all 100 and 300 Series HP Latex printers. HP Latex Print & Cut Bundle Solutions, as well as HP Latex cutters include HP Flexi Print & Cut 12 software. This RIP includes specific tools to promote productivity gains for banner production.

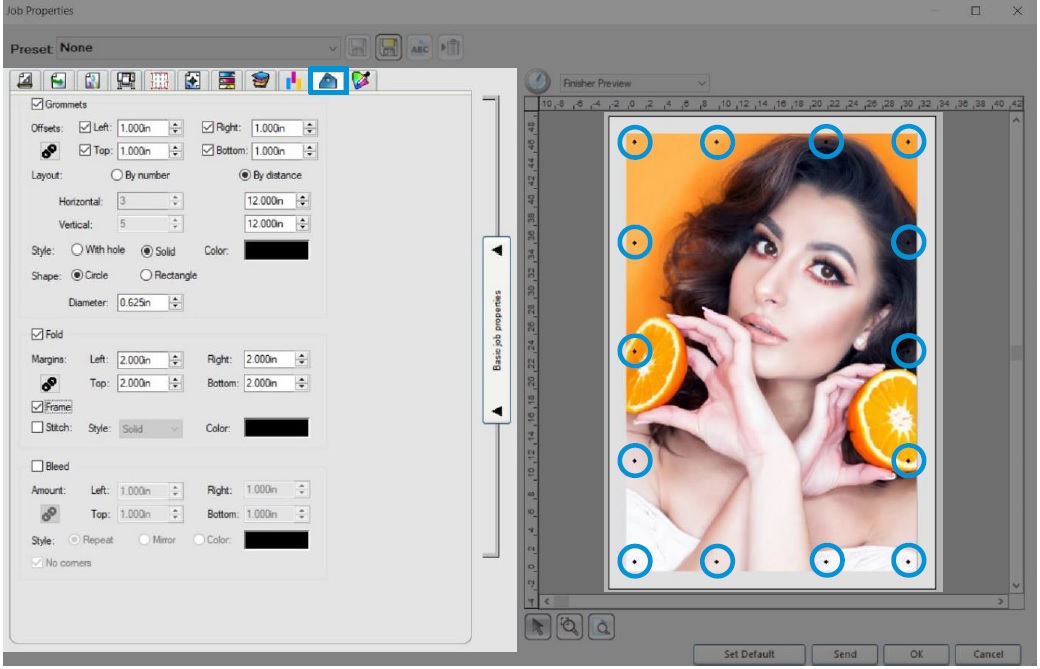

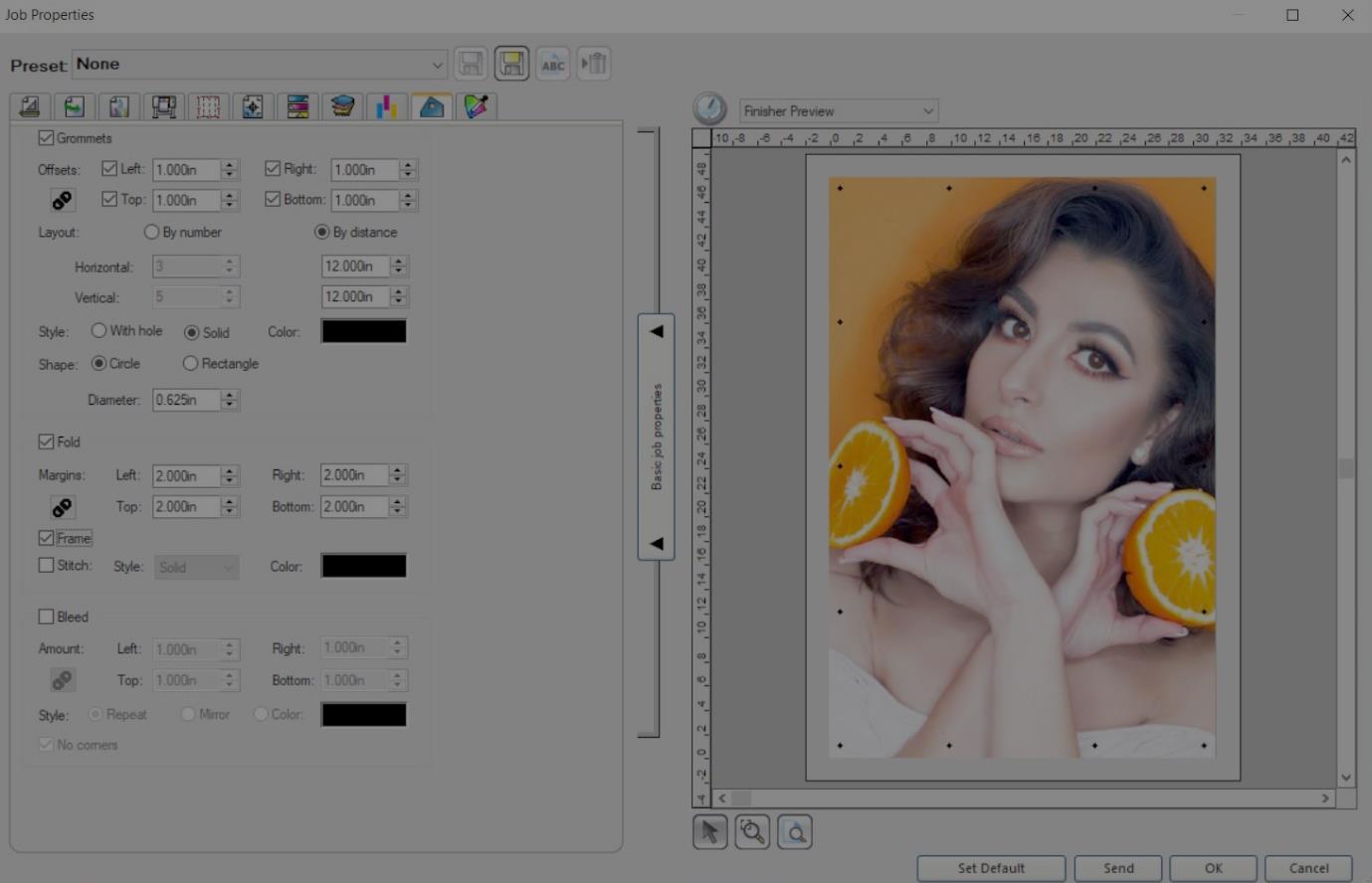

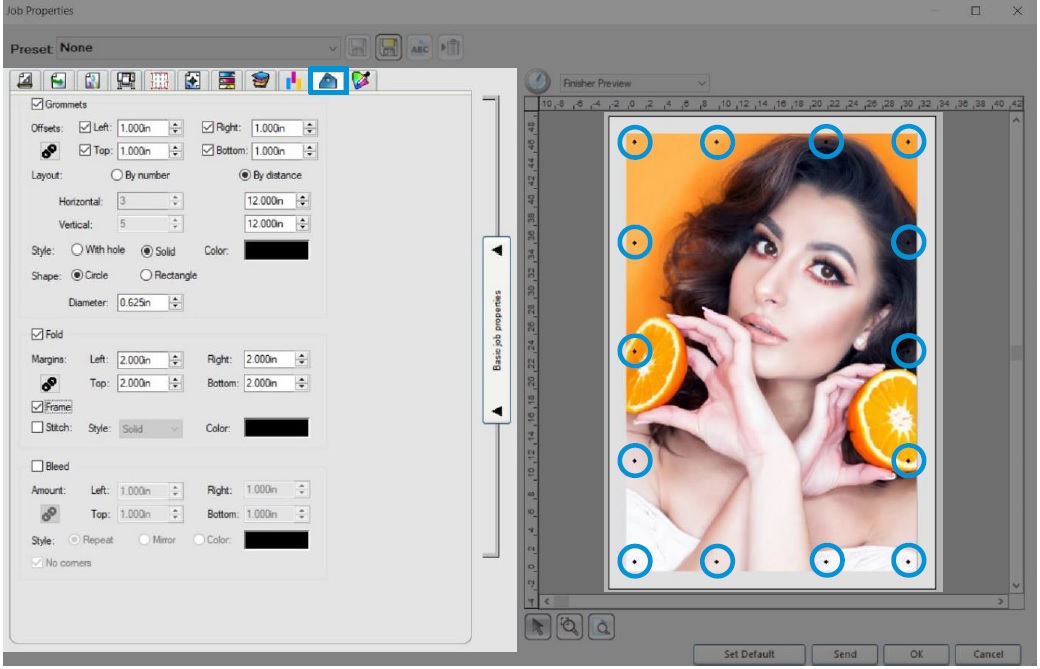

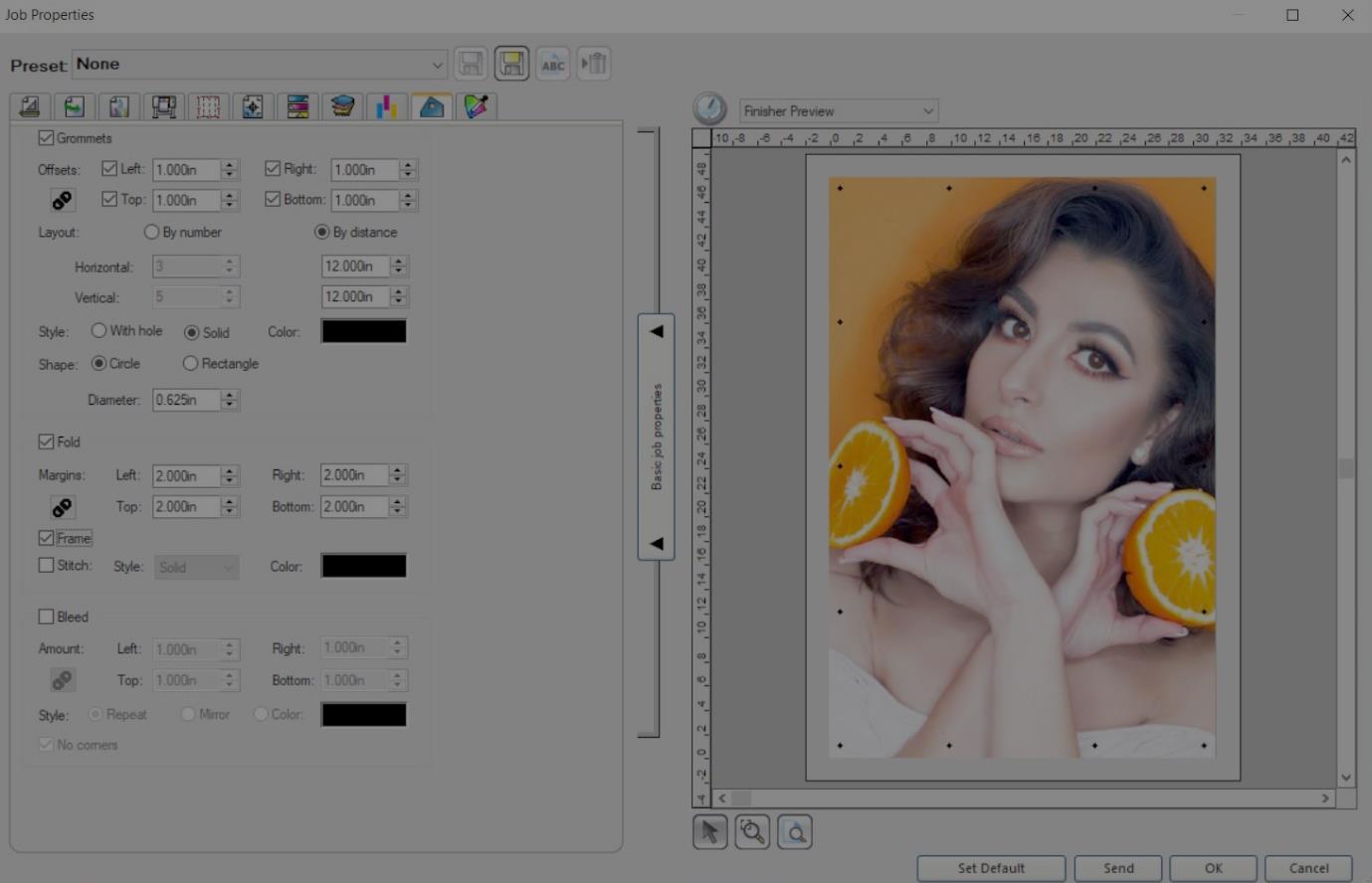

The following tools are located on the Finisher Tab in the Job Properties dialog:

• Grommet Marks

• Fold Marks

• Frame Marks

• Bleed

These tools create printed marks for the selected mark type at the desired frequency or distance.

In this screen, we have defined grommets every 12 inches, with a 2-inch fold margin with frame on the edge of the print. This makes finish cuts fast and easy.

5. Media Loading Tips for Banners

Loading many banner media into HP Latex 100, 300, and 500 Series printers is a simple task, but there are things to consider. Banner media are available in two wind directions – forward wound (print side out) and reverse wound (print side in). Either is compatible with HP Latex printers, but many users report that forward wound media tends to be easier to load, particularly for new users of HP Latex printers.

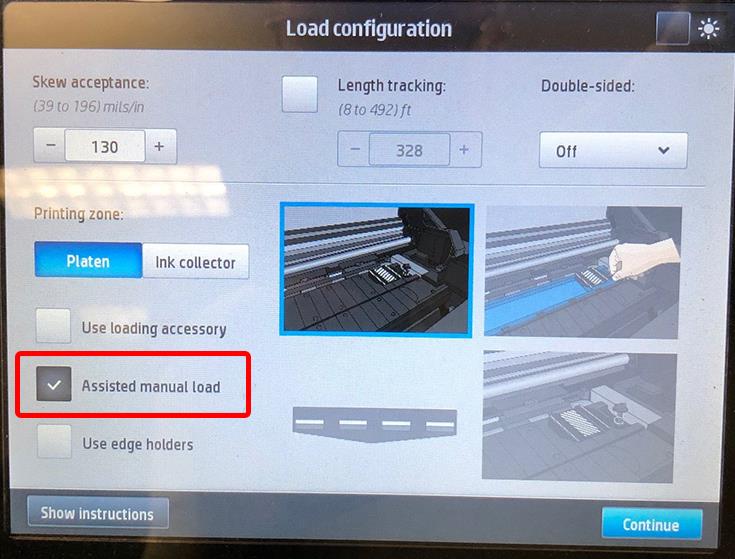

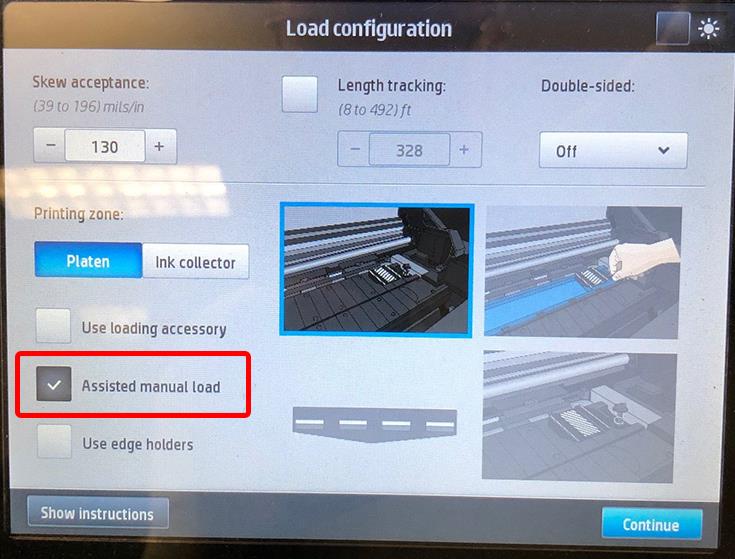

Latex 100, 300, and 500 Series printers offer the operator two options for loading media:

• Auto Load

• Assisted Manual Load

Both options work well for banner media. The choice is a checkbox in the Load Configuration screen on the Front Panel, called Assisted Manual Load. When disabled Auto Load is used, and when enabled Assisted Manual Load is enabled. The following image illustrates this function:

|

After deciding which loading approach to use, tap the Continue button and follow the prompts to manually load the banner media as prompted on the Front Panel.

If using Assisted Manual Load, manually advance the media through the media path until the leading edge has passed through the curing unit.

Next, the printer will prompt you to define a media category and media product. After choosing the media name, the printer will check for skew (lateral movement of the media), then automatically check the media width and (300 and 500 series) substrate advance calibration before coming to a ready state. |

After the printer comes to a ready state, the operator can manually advance or retract the media from the Front Panel by tapping Substrate > Move > [direction].

6. Printing

Printing to HP Latex printers is performed using RIP software, rather than through driver-based workflows. Some HP Latex printers ship with RIP software, including the 100 and 300 Series printers. 500 Series printers do not include RIP software. HP Certifies a wide range of RIPs from ONYX, Caldera, SAI, Colorgate, Ergosoft, etc. Other RIPs may support HP Latex printers, but their complete compatibility has not been validated by HP.

HP bundles versions of the SAI RIP software in Latex 300 Series printers. 310/315 and 330/335 printers bundle the SAI Flexi Basic RIP. The Latex 365 also includes the Flexi Basic RIP. When the Basic RIP is used to drive the printer, the job file must be created using design software. Widely used design software titles include Adobe Photoshop, In Design, and Illustrator, CorelDRAW and PhotoPAINT, Inkscape, and Affinity Designer. RIPs commonly support a wide range of file formats, including TIF, JPG, PDF, and EPS files, among others.

The image below shows the Layout Tab of Job Properties in the SAI RIP. On this tab are located a range of tools that relate to where, how large, and how many copies of the job will be output, with an accurate preview of the layout on the right side of the dialog. Clicking Send will process the job and send it to the printer.

7. Finishing

After printing, banners generally require finishing activities. These can be grouped into several categories of task:

• Cutting and trimming

• Hemming

• Adding Grommets / Mounting Hardware

It is important to note that the X-trimmer (separate sheet) on the printer does not work with banner media. This means that banner media needs to be separated from the roll using scissors or a blade. Once separated from the roll, finish cuts are often required.

Many users employ a straight or rotary blade for these cuts, along with a long straight edge or ruler. Popular finishing tools include rotary trimmers from companies like Keencut, Dahle, Rotatrim, Neolt, and more.

Users who produce relatively low quantities of banners tend to use double-sided hem tape or single-sided film tape to provide reinforcement for the banner edges. This approach provides an effective and low-cost solution to banner finishing.

Those who produce higher volumes of banners each month may prefer to finish using a double needle industrial sewing machine. An additional option for banner finishing is to weld them.

8. Useful links

You can find templates to use at HP Application Center.

- Open the Roll-ups app at www.hpapplicationscenter.com.

- Select the “Backgrounds” tab from the left hand navigation bar.

- For editable social distancing and general hygienic themed templates, select the “COVID-19” folder.

- For illustrations to create your own poster, select the “Objects” tab on the left, and choose “COVID-19”.

PrintOS Media Locator:

• https://www.printos.com/ml/#/homeMediaLocator

Further information:

• http://www.hp.com/supportvideos

• http://www.youtube.com/HPSupportAdvanced